Phew! Easy does it drilling

Some of the drill bits I use for drilling stone

Drilling stone can be hard work. At the very least carbide tipped ‘masonry’ drills are needed. I’ve always found it difficult to keep the drill steady and straight, but I’m getting better with practice. Often the base of a sculpture needs drilling, so that it can be secured in place on site and I drill holes in my pots and planters for drainage.

One of my drill bits – you can see clearly the carbide insert, which has been brazed into the tip, making it very strong and durable

One of my oldest, and most used drill bits – an ugly thug of a thing, but works like a dream

Stone can so easily chatter and break off at the edges around the drill hole, which I hate to see – going steady and sharp drill bits help.

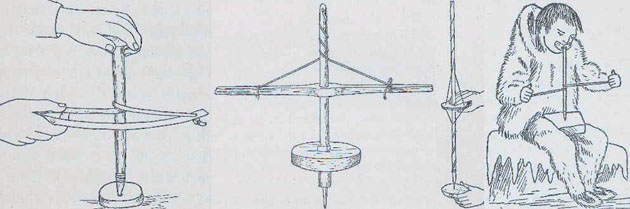

Strap or Cord drill – image via

Really though, we have it easy now – powerful motors at the flick of a switch and ‘hammer’ action if required. In times past bow drills and laborious spinning by hand was needed. In Roman times the standard type of drill was a strap, or cord drill. It consisted of a chisel-like metal tool set into a shaft connected to a wooden handle within which it rotated freely. The shaft was driven by pulling back and forth on a cord wrapped around it several times. The cord was operated by one person while another directed the drill itself, deciding where the bit was placed and applying pressure on the handle.

Thank goodness we’ve progressed! How often is a drilling chum around when you need them or imagine holding and exerting pressure on the drill with the mouth!